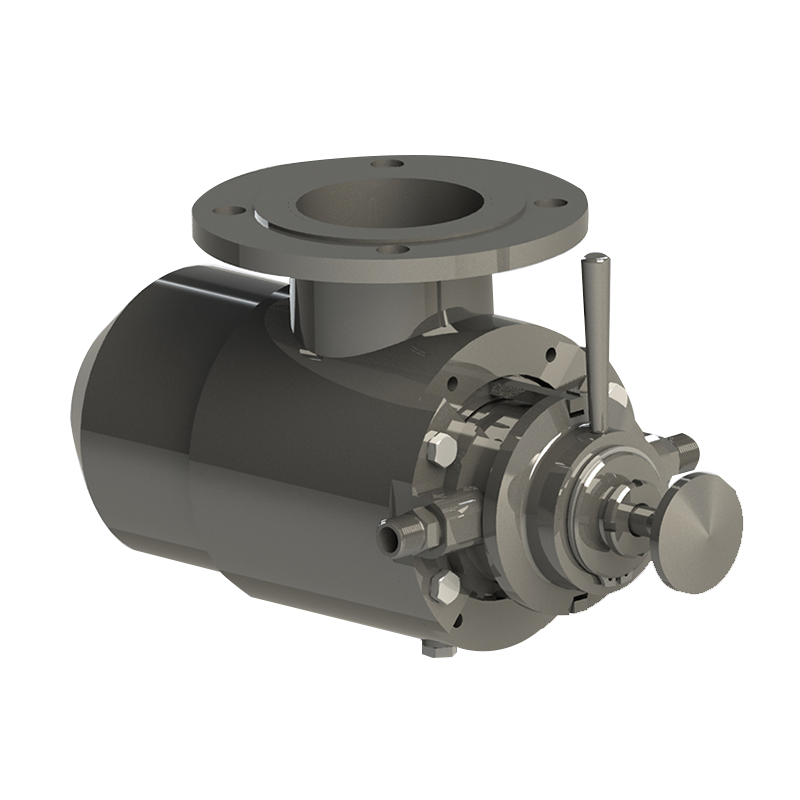

1、低压燃油烧嘴原理:

1) 喷嘴的油压在49~894kPa范围内变动,利用燃油本身的油压改变,使供油量变化,与此同时,自动地按一定比例使空气量也相应变化。因此在燃烧能力变化时,能完全自动地保证一定的风油配比,达到完全燃烧,空气过剩量小,可获得良好的燃烧效果,同时提高生产率,节省燃料消耗,消除烟尘,减少氧化烧损。

2) 由于喷嘴本身就能够使油与空气自动配比,成为一个自动调节器,为燃油工业炉燃烧过程的集中控制和自动化创造了有利条件,特别对大型工业炉多喷嘴多段供热的燃油系统,无论手动和自动,均具有群控、自控方便、系统简单、调整容易等突出优点。

1. Burner principle:

1) The oil pressure of the nozzle varies within the range of 49 ~ 894kPa. Adjusting the oil pressure changes the flow of oil and automatically scales the flow of air. When the combustion capacity changes, it can completely automatically ensure a certain proportion of air oil to achieve complete combustion. The minimum excess air can obtain the best combustion effect. At the same time, improve productivity, save fuel consumption, eliminate smoke and dust, reduce oxidation burning loss.

2) The nozzle can be automatically adjusted, which creates favorable conditions for the centralized control and automation of the combustion process of the oil industry furnace. It has the advantages of group control, convenient automatic control, simple system, easy adjustment and so on, especially for the fuel system with multi-nozzle and multi-stage heating of large industrial furnace.

2、应用场合:

1) 广泛运用在各种液体低压工业燃烧炉上,可作为:加热炉烧嘴、退火炉烧嘴、多膛炉、还原炉烧嘴、炉窑烧嘴、烘干机烧嘴、其他高温应用。

2. Applications:

1) Widely used in all kinds of liquid low-pressure industrial combustion furnace, such as: heating furnace burner, annealing furnace burner, multi-chamber furnace, reducing furnace burner, furnace burner, dryer burner and other high temperature applications.

3、产品特点:

1) 能实现冷态电子自动点火;

2) 燃油雾化效果好,燃油雾化颗粒度小,尺寸分布均匀;

3) 燃烧充分、不冒黑烟;

4) 燃烧安全、运行稳定,燃烧效率在99.9%以上;

5) 解决不稳定、结焦堵塞问题,无回火、脱火现象;

6) 火焰长度、锥角及形状可按用户要求设计;

7) 燃烧器安装方式可根据用户需求;

8) 燃油流量:2kg/h-500kg/h(根据用户要求设计)

3. Product features:

1) Realize electronic automatic ignition;

2) Good fuel atomization, small fuel atomization particle size, uniform size distribution;

3) Completely burning without black smoke;

4) Combustion safety, stable operation, combustion efficiency of more than 99.9%;

5) Solve the problems of instability and coking blockage without tempering or defiring;

6) Flame length, cone angle and shape can be designed for user requirements;

7) The burner installation method can be based on user requirements;

8) Fuel flow: 2 kg/h-500 kg/h (designed for user requirements)